Dati principali / Realizzazioni |

|

|---|---|

| Capacità produttiva | 254.000 t/a |

Impianto produzione lamiere bonficate

| Sito: | Clabecq (B) |

| Attività: | EPC |

| Anno: | 2011 |

| Cliente: | Duferco Clabecq |

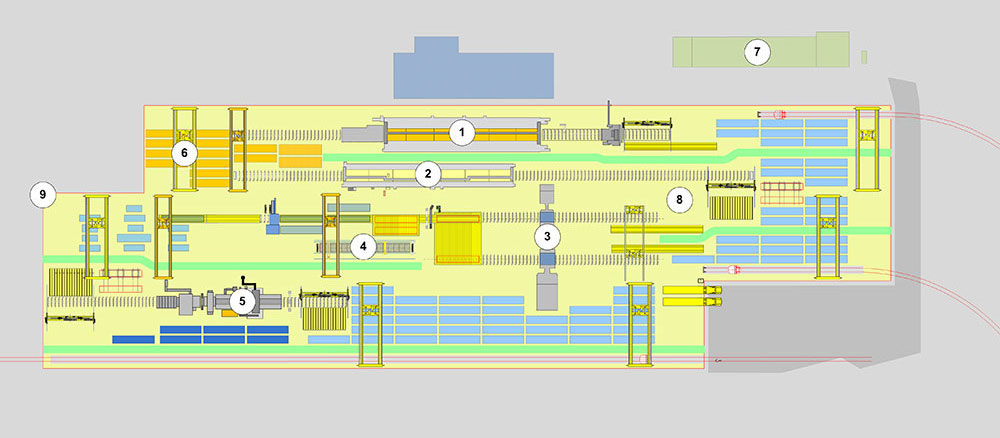

The normalizing line

- 1 Longitudinal Package Conveyor (40 meters; 25 ton)

- 1 Fast Plate Manipulator with vacuum pads (18 meters; 15 ton)

- 1 Shot Blasting Machine;

- 1 Paint Marking Machine for tracking;

- 1 Austenitic Furnace (65 meters ; 22 t/h)

- 1 Continuous Roller Quench (18 meters; 4 bar and 8 bar);

- 96 meters of single drive roller tables (pitch 750 mm; 900 mm and 1.000 mm) with n.1 centering device

The tempering line

- 1 Tempering Furnace (40 meters; 25 ton);

- 1 Fast Plate Manipulator with magnets for discharging the line (18 meters; 25 ton);

- 1 Transversal Package Conveyor (25 ton);

- 130 meters of single drive roller table (pitch 1.000 mm; hollow rolls and disc rolls) with 1 centring device

The levelling lines

- 1 Over Head Fast Plate Manipulator (6 meters; 25 ton);

- 2 Longitudinal Package Conveyors (40 meters; 25 ton);

- 76 meters of belt conveyors;

- 100 meters multi drive roller table (pitch 1.000 mm) with n. 2 centring device;

- 1 Plate Transfer Bed with chain (15 ton; 350 sqm);

- 1 Hydraulic Leveler for Thin Plates (3 mm 12 mm); Leveling Force 14.000 kN;

- 1 Hydraulic Leveler for thick Plates (10 mm 25 mm); Leveling Force 40.000 kN;

- 2 Flatness Gauge Measurers.

The cutting lines

- 100 meters of single drive Roller Table (pitch 1.000 mm);

- 1 Transversal Conveyor;

- 1 Hardness Tester Measurer on line;

- 1 Bridge Paint Marking Machine for tracking and for final marking;

- 1 Double position Plasma Cutting Bench (40 meters; 4 plasma torches; 1 service portal for scrap removal);

- 1 Hydraulic Cut to length Shear.

The painting lines

- 80 meters of single drive Roller Table (pitch 1.000 mm)

- 2 Transversal Package Conveyors;

- 2 Fast Plate Manipulators;

- 1 Shot Blasting Machine;

- 1 Painting Cabin with mixing painting room (solvent and water based paint);

- 1 drying oven (30 meters);

- 1 SOV burner;

- 1 final customer paint marking machine.

The handling equipment

- N. 6 Over Head Cranes (14 m height; 33 meters span ; 40 T hook capacity);

- N. 3 Over Head Manipulators (7 m height; 33 meters span ; 25 t hook capacity);

- N. 1 Electromechanical Grab;

- N. 8 Magnets (of which 6 electromagnet; 1 permanent magnet ; 1 tropical magnet);

- N. 2 Package Conveyors on wheels.

The water treatment plant

- N. 10 Main Pumps for Contact Water Circuit (Water for Quench);

- N. 6 minor pumps for recirculation and non contact water;

- N. 11 Forced Cooling Tower Air – Water; 1 Non Contact water – water Heat Exchanger.

The electrical distribution

- N. 1 Main Trafo ONAN 22 MVA (36 KV 15 kV);

- N. 14 Trafo 15 kV Low Voltage;

- N. 31 Metal Clad 15 kV cubicles;

- N. 52 Main Low Voltage Breakers (Power Centers);

- 31 km of power cables.

The buildings and CW

- Overall surface : 36.000 m2:

- Internal area 31.000 m2

- External area 5.000 m2

- Building Steel Structures : 3.058 tons;

- Building claddings : 42.929 m2;

- Burback Rails for Cranes : 2.286 m;

- Drillen Piles 12.000 kN ø 6001.279 m;

- Micropiles 1.626 m;

- Plynths : n. 70 (1.348 m3 – 67.953 kg rebar)

- Machine Foundation : 17.257 m3; 1.507.000 kg rebar;

- Industrial floor : 16.940 m2;

- Lean Concrete : 4.153 m3;

- Demolition and excavation : 70.673 m3